|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

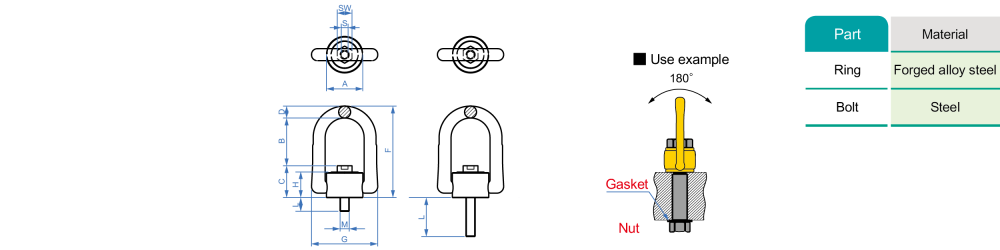

| unit:mm | |

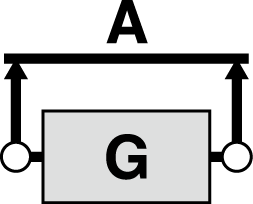

| Ultimate load | M | Pitch | L | SW | B | C | A | G | R | F | S | D | H | Locking | Weight kg | ||

| Short thread | Long thread | torque | Short thread | Long thread | |||||||||||||

| 0.5 | M8 | 1.25 | 12 | 83 | 13 | 42 | 28 | 33 | 58 | 17 | 80 | 6 | 11 | 23 | 30 | 0.3 | 0.3 |

| 0.7 | M10 | 1.5 | 15 | 103 | 17 | 41 | 29 | 60 | 0.3 | 0.3 | |||||||

| 1 | M12 | 1.75 | 20 | 128 | 19 | 40 | 31 | 8 | 100 | 0.3 | 0.3 | ||||||

| 2 | M16 | 2 | 24 | 149 | 24 | 54 | 46 | 50 | 90 | 27 | 117 | 10 | 17 | 36 | 150 | 0.9 | 0.9 |

| 3 | M20 | 2.5 | 30 | 194 | 30 | 52 | 49 | 50 | 90 | 27 | 117 | 12 | 17 | 36 | 250 | 1 | 1 |

| 5 | M24 | 3 | 36 | 221 | 36 | 81 | 59 | 72 | 125 | 37 | 163 | 14 | 25 | 44 | 400 | 2.6 | 2.6 |

| 7.8 | M30 | 3.5 | 48 | 278 | 46 | 94 | 81 | 87 | 148 | 46 | 204 | 17 | 30 | 62 | 500 | 50 | 50 |

| 12.5 | M36 | 4 | 54 | 225 | 55 | 112 | 98 | 110 | 188 | 57 | 247 | 22 | 36 | 75 | 1000 | 9.6 | 9.6 |

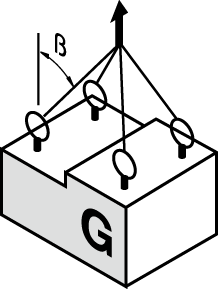

| Hanging icon |

|

|

|

|

|

|

|

| ||

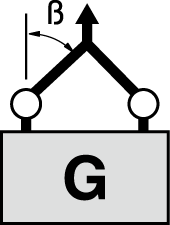

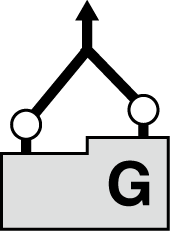

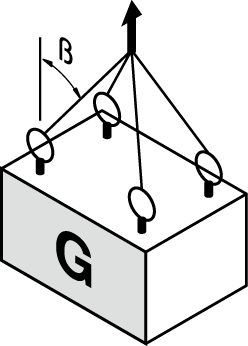

| count | 1 | 2 | 1 | 2 | 2 | 2 | 2 | 3~4 | 3~4 | 3~4 |

| Load angle | 0° | 0° | 90° | 90° | 0°45° | 45°60° | Asymmetrical on both sides | 0°45° | 45°60° | Asymmetrical on both sides |

| Thread | Load limit Tons | |||||||||

| M8 | 0.8 | 1.6 | 0.5 | 1 | 0.7 | 0.5 | 0.5 | 1.1 | 0.8 | 0.5 |

| M10 | 1.2 | 2.4 | 0.7 | 1.4 | 1 | 0.7 | 0.7 | 1.5 | 1.1 | 0.7 |

| M12 | 2 | 4 | 1 | 2 | 1.4 | 1 | 1 | 2.1 | 1.5 | 1 |

| M16 | 3.2 | 6.4 | 2 | 4 | 2.8 | 2 | 2 | 4.2 | 3 | 2 |

| M20 | 5.6 | 11.2 | 3 | 6 | 4.2 | 3 | 3 | 6.3 | 4.5 | 3 |

| M24 | 9.2 | 18.4 | 5 | 10 | 7 | 5 | 5 | 10.5 | 7.5 | 5 |

| M30 | 12 | 24 | 7.8 | 15.6 | 10.9 | 7.8 | 7.8 | 16.4 | 11.7 | 7.8 |

| M36 | 14 | 28 | 12.5 | 25 | 17.5 | 12.5 | 12.5 | 26.3 | 18.8 | 12.5 |

※Note

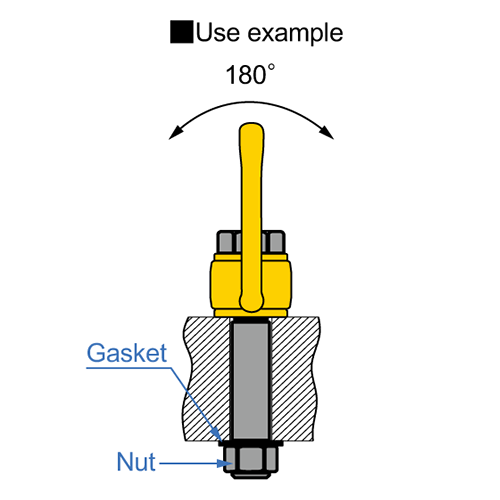

•It can be rotated by 360° and rotated by 180°, and can be adjusted in any direction.

•All rings are manufactured in accordance with the relevant European standard EN1677-1.

•The wrought alloy steel used on the rotating sling is quenched and tempered.

•Batch numbers are printed on all forged parts and cap screws to facilitate inspection and verification on the quality certification instructions.

•The bolts are of uniform metric thread (ASME/SNSI B18.3.1 M) and are available in DIN EN ISO 4762.

•Verify that the load is 2.5 times the load limit. · The force of 1.5 times the load limit is tested for fatigue limit of 20,000 times.

•Only the screw holes are required for the object to be lifted, and it can be installed with a flat head/head wrench or an Allen key.