|

|

|

|

|

|

|

|

|

|

|

|

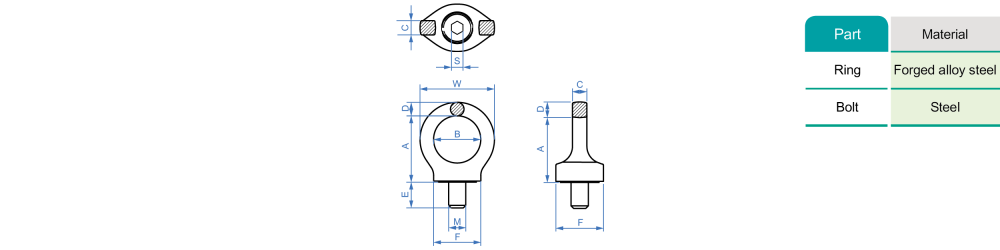

| unit:mm | |

| Ultimate load | M | Pitch | E | W | S | B | C | D | A | F | Locking torque | Weight | |

| 0.3 | M8 | 1.25 | 12 | 44 | 6 | 25 | 8 | 9 | 36 | 25 | 10 | 0.1 | |

| 0.4 | M10 | 1.5 | 15 | 44 | 6 | 25 | 8 | 9 | 36 | 25 | 10 | 0.1 | |

| 0.75 | M12 | 1.75 | 18 | 52 | 8 | 30 | 10 | 11 | 45 | 33 | 10 | 0.2 | |

| 1.5 | M16 | 2 | 24 | 61 | 10 | 35 | 14 | 13 | 52 | 35 | 30 | 0.3 | |

| 2.3 | M20 | 2.5 | 30 | 70 | 12 | 40 | 16 | 15 | 60 | 44 | 70 | 0.6 | |

| 3.2 | M24 | 3 | 36 | 84 | 14 | 48 | 19 | 18 | 72 | 52 | 150 | 1 | |

| 4.5 | M30 | 3.5 | 45 | 105 | 17 | 60 | 24 | 22 | 90 | 60 | 350 | 1.8 | |

| 7 | M36 | 4 | 54 | 126 | 22 | 72 | 29 | 27 | 109 | 76 | 410 | 3.2 | |

| 9 | M42 | 4.5 | 63 | 147 | 24 | 82 | 34 | 32 | 123 | 88 | 55 | 5 | |

| 12 | M48 | 5 | 72 | 168 | 27 | 94 | 38 | 37 | 144 | 104 | 55 | 7.6 | |

| 16 | M56 | 5.5 | 84 | 178 | 27 | 102 | 40 | 43 | 147 | 124 | 800 | 9.2 | |

| 18 | M64 | 6 | 95 | 178 | 27 | 102 | 40 | 43 | 147 | 130 | 800 | 10 |

■Ring load table

| Ring load table |

|

|

|

|

|

|

|

| |||

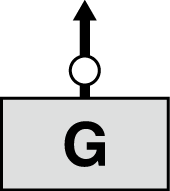

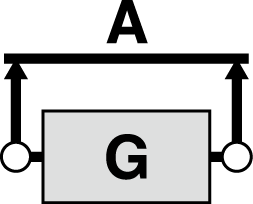

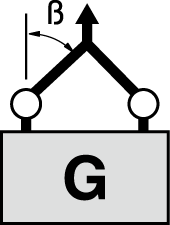

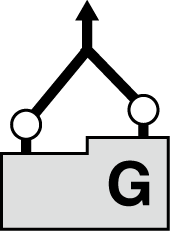

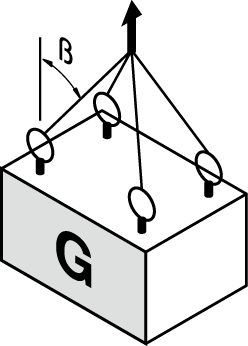

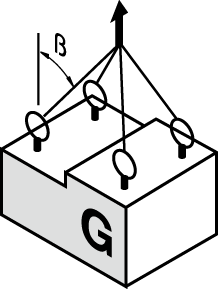

| count | 1 | 2 | 1 | 2 | 2 | 2 | 2 | 3~4 | 3~4 | 3~4 | |

| Load angle | 0° | 0° | 90° | 90° | 0°~45° | 45°~60° | Asymmetrical on both sides | 0°~45° | 45°~60° | Asymmetrical on both sides | |

| Thread | Load limit Tons | ||||||||||

| M8 | 1 | 2 | 0.3 | 0.6 | 0.42 | 0.3 | 0.3 | 0.63 | 0.45 | 0.3 | |

| M10 | 1 | 2 | 0.4 | 0.8 | 0.56 | 0.4 | 0.4 | 0.8 | 0.6 | 0.4 | |

| M12 | 2 | 4 | 0.75 | 1.5 | 1 | 0.75 | 0.75 | 1.5 | 1.1 | 0.75 | |

| M16 | 4 | 8 | 1.5 | 3 | 2.1 | 1.5 | 1.5 | 3.1 | 2.2 | 1.5 | |

| M20 | 6 | 12 | 2.3 | 4.6 | 3.2 | 2.3 | 2.3 | 4.8 | 3.4 | 2.3 | |

| M24 | 8 | 16 | 3.2 | 6.4 | 4.5 | 3.2 | 3.2 | 6.7 | 4.8 | 3.2 | |

| M30 | 12 | 24 | 4.5 | 9 | 6.3 | 4.5 | 4.5 | 9.4 | 6.7 | 4.5 | |

| M36 | 16 | 32 | 7 | 14 | 9.8 | 7 | 7 | 14.7 | 10.5 | 7 | |

| M42 | 24 | 48 | 9 | 18 | 12.6 | 9 | 9 | 18.9 | 13.5 | 9 | |

| M48 | 32 | 64 | 12 | 24 | 16.8 | 12 | 12 | 25 | 18 | 12 | |

| M56 | 34 | 68 | 16 | 32 | 22.4 | 16 | 16 | 32 | 24 | 16 | |

| M64 | 36 | 72 | 18 | 36 | 25.2 | 18 | 18 | 36 | 27 | 18 | |

※Note

•It can be rotated 360° to adjust the angle with the direction of force.

•The rings are made of wrought alloy steel and are quenched and tempered.

•The rings are manufactured and tested in accordance with the relevant European standard EN1677-1.

•The product is inspected by 100% magnetic particle inspection.

•All forged parts and hex bolts can be traced by quality inspection reports.

•The bolts are UNC threads and comply with US Standard ASME/ANISI B18.2.1.

•內The specifications of hexagonal alloy steel bolts comply with the European Union Directive DIN EN ISO 4762.

•Verify that the load is 2.5 times the working limit load.

•The fatigue limit test was performed 20,000 times with a force of 1.5 times the working limit load.

•Only the screw holes are required for the object to be lifted, and the hex wrench is used for installation.

►Obtained a Chinese patent ►Obtained a French patent ►Obtained Australian patent