💦There are discounts for orders above 10.

🟡Standard hole diameter is free; keyway: extra charge.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

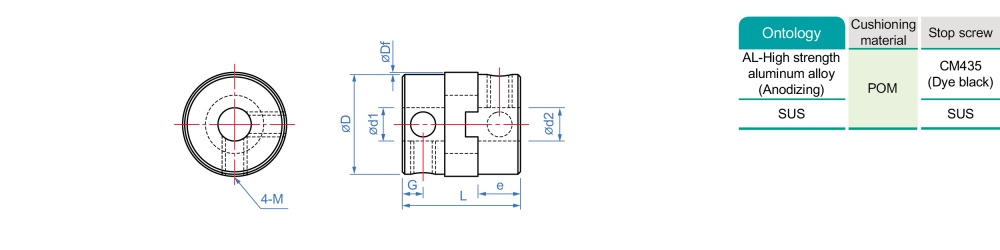

| unit:mm | |||

| D | L | The inner bore is specified | Df | e | M | G | Maximum torque | highest | Moment of inertia | Static torsion | allow Axial displacement | Permissible declination | Quality | ||||

| AL | SUS | AL | SUS | AL | SUS | AL | SUS | ||||||||||

| 12 | 14.2 | 4~6 | 0.25 | 5.1 | M3 | 2.5 | 0.7 | 1 | 9000 | 7.0 x 10-8 | 1.5x10-7 | 44 | ±0.2 | 2° | 2.5° | 5.1 | 8.5 |

| 14.5 | 16 | 4~6 | 5.3 | 3 | 1 | 1.5 | 7000 | 1.6 x 10-7 | 3.2x10-7 | 90 | 3° | 8 | 15 | ||||

| 17 | 19.8 | 5~8 | 0.35 | 6.75 | M4 | 3.2 | 1.3 | 2 | 6500 | 3.75x 10-7 | 7.5x10-7 | 220 | 3.2° | 13 | 25 | ||

| 20 | 21.4 | 5~10 | 0.5 | 7.05 |

| 2 | 3 | 5000 | 8.0 x 10-7 | 1.7x10-6 | 320 | 3.8° | 17 | 37 | |||

| 26 | 25.6 | 5~14 | 9.05 | 3.8 | 3.75 | 5 | 2.9 x 10-6 | 5.8x10-6 | 380 | ±0.25 | 39 | 79 | |||||

| 30 | 33 | 5~16 | 12.1 | 5.8 | 9.5 | 12 | 9.0 x 10-6 | 1.8x10-5 | 1000 | 6.1 | 122 | ||||||

| 34 | 34.2 | 5~16 | 12.9 | M5 |

| 10 | 15 | 3500 | 1.1 x 10-5 | 2.2x10-5 | 2200 | 5.5° | 90 | 180 | |||

| 38 | 40 | 5~18 | 1.5 | 15.2 | 7 | 17.5 | 25 | 2.8 x 10-5 | 7.5x10-5 | 3200 | 7° | 130 | 260 | ||||

| 45 | 43.6 | 8~25 | 15 | 7.5 | 19 | 30 | 9000 | 8.5 x 10-5 | 1.7x10-4 | 3500 | ±0.35 | 2.5° | 7.5° | 200 | 400 | ||

| 55 | 49.4 | 10~30 | 17 | M6 | 8.5 | 22 | 35 | 1.6 x 10-4 | 3.3x10-4 | 4200 | 8.5° | 375 | 750 | ||||

| 70 | 57 | 12~38 | 2 | 20 | M8 | 11 | 30 | 45 | 5.5 x 10-4 | 1.1x10-3 | 5800 | 11° | 400 | 1300 | |||