| ||||||||||||||||||||||||||||||||||||||

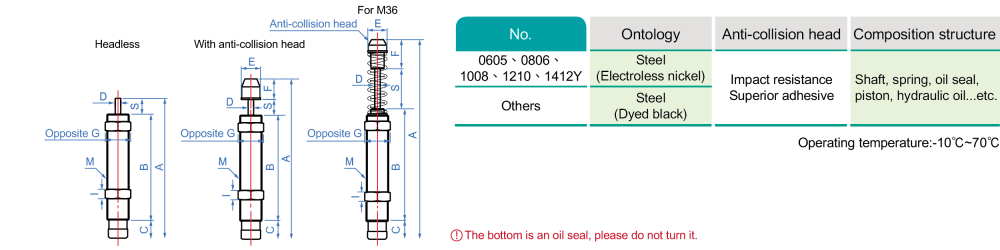

| M6X0.5 | 5 | 0605 | A | 0.6~2.8 | 1.8 | 0.9 | 32 | 37 | 33 | 21.5 | 4 | 1.8 | 5 | 4 | 2.5 | 8 |

| B | 1.2~3.7 | 1.2 | ||||||||||||||

| M8X1.0 | 6 | 0806 | A | 1~5.6 | 2 | 1.8 | 72 | 53 | 44.5 | 34 | 4.5 | 2.8 | 6.6 | 8.5 | 3 | 11 |

| B | 2.5~10 | 1.2 | ||||||||||||||

| C | 5.6~22 | 0.8 | ||||||||||||||

| M10X1.0 | 5 | 1005 | A | 1~4.2 | 2.4 | 2 | 80 | 38.5 | 32.5 | 21.5 | 6 | 3 | 8.6 | 6 | 3 | 12.7 |

| B | 2.5~8 | 1.2 | ||||||||||||||

| C | 10~35 | 0.8 | ||||||||||||||

| 8 | 1008 | A | 0.9~10 | 2.6 | 3.2 | 128 | 62 | 53.5 | 41 | 4.5 | 3 | 8.6 | 8.5 | 3 | 12.7 | |

| B | 2.8~17 | 1.5 | ||||||||||||||

| C | 10~40 | 0.8 | ||||||||||||||

| M12X1.0 | 10 | 1210 | A | 1.8~18 | 2.6 | 6 | 240 | 72 | 62.5 | 47.7 | 4.8 | 3 | 10 | 9.5 | 4 | 14 |

| B | 5.3~33 | 1.5 | ||||||||||||||

| C | 12~75 | 0.8 | ||||||||||||||

| M14X1.5 | 12 | 1412Y | A | 4.7~32 | 2.6 | 16 | 480 | 80.4 | 67 | 50.2 | 4.8 | 3.5 | 12.2 | 13.4 | 6 | 19 |

| B | 14~65 | 1.5 | ||||||||||||||

| C | 56~200 | 0.8 | ||||||||||||||

| 12 | 1412 | A | 4.7~32 | 2.6 | 16 | 480 | 92.7 | 79.3 | 59.3 | 8 | 3.5 | 12.2 | 13.4 | 6 | 19 | |

| B | 14~65 | 1.5 | ||||||||||||||

| C | 56~200 | 0.8 | ||||||||||||||

| 15 | 1415 | A | 6~40 | 2.6 | 20 | 600 | 103.5 | 90 | 67 | 8 | 3.5 | 12.2 | 13.4 | 6 | 19 | |

| B | 17~81 | 1.5 | ||||||||||||||

| C | 62~250 | 0.8 | ||||||||||||||

| 25 | 1425 | A | 6~40 | 2.6 | 28 | 980 | 133.5 | 120 | 87 | 8 | 3.5 | 12.2 | 13.4 | 6 | 19 | |

| B | 17~81 | 1.5 | ||||||||||||||

| C | 62~250 | 0.8 | ||||||||||||||

| M20X1.5 | 20 | 2020 | A | 6.8~27 | 3.2 | 35 | 700 | 130 | 114 | 85 | 9 | 5 | 17.8 | 16 | 8 | 26 |

| B | 17~70 | 2 | ||||||||||||||

| C | 48~777 | 1 | ||||||||||||||

| 30 | 2030 | A | 9~36 | 3.2 | 46 | 920 | 158 | 一 | 103 | 9 | 5 | 17.8 | 16 | 8 | 26 | |

| B | 23~92 | 2 | ||||||||||||||

| C | 64~575 | 1.2 | ||||||||||||||

| 50 | 2050 | A | 10~124 | 3.5 | 62 | 1054 | 222 | 一 | 147 | 9 | 5 | 17.8 | 16 | 8 | 26 | |

| B | 18~253 | 2.6 | ||||||||||||||

| C | 55~496 | 1.5 | ||||||||||||||

| M25X1.5 | 25 | 2525 | A | 15~69 | 3.2 | 78 | 1170 | 152.5 | 136 | 101 | 10 | 8 | 23 | 16.5 | 10 | 32 |

| B | 39~433 | 2 | ||||||||||||||

| C | 108~1733 | 1.2 | ||||||||||||||

| 40 | 2540 | A | 20~108 | 3.5 | 122 | 1464 | 211 | 一 | 127 | 10 | 8 | 23 | 34 | 10 | 32 | |

| B | 50~381 | 2.2 | ||||||||||||||

| C | 244~1991 | 1 | ||||||||||||||

| 50 | 2550 | A | 20~124 | 3.7 | 140 | 1680 | 226.5 | 一 | 150 | 10 | 8 | 23 | 16.5 | 10 | 32 | |

| B | 48~438 | 2.4 | ||||||||||||||

| C | 194~2286 | 1.2 | ||||||||||||||

| 80 | 2580 | A | 24~99 | 4 | 198 | 1980 | 333.5 | 一 | 150 | 10 | 8 | 23 | 16.5 | 10 | 32 | |

| B | 44~396 | 3 | ||||||||||||||

| C | 176~1584 | 1.5 | ||||||||||||||

| M27X1.5 | 25 | 2725 | A | 15~69 | 3.2 | 78 | 1170 | 152.5 | 136 | 101 | 10 | 8 | 23 | 16.5 | 10 | 32 |

| B | 39~433 | 2 | ||||||||||||||

| C | 108~1733 | 1.2 | ||||||||||||||

| M36X1.5 | 60 | 3660 | A | 57~231 | 3 | 260 | 2080 | 247 | 一 | 154 | 11 | 10 | 36 | 22 | 15 | 46 |

| B | 130~813 | 2 | ||||||||||||||

| C | 520~3250 | 1 |