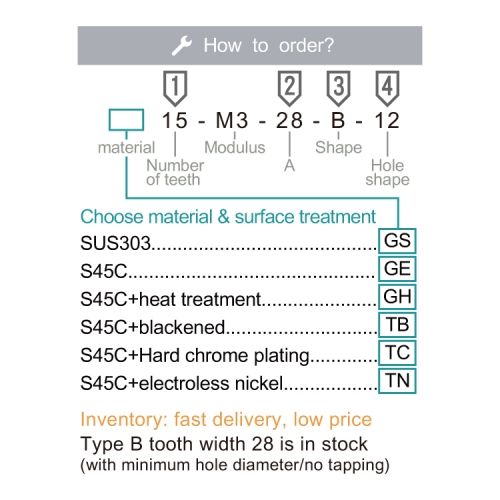

M3 module

Metal gear Pressure angle 20∘

Belt teeth

Type

Please select a size

Quantity

In stock

Remark

|

|

|

|

|

|

|

|

|

|

| unit:mm | |

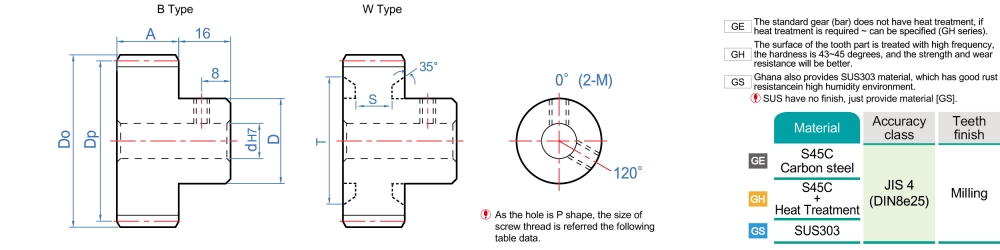

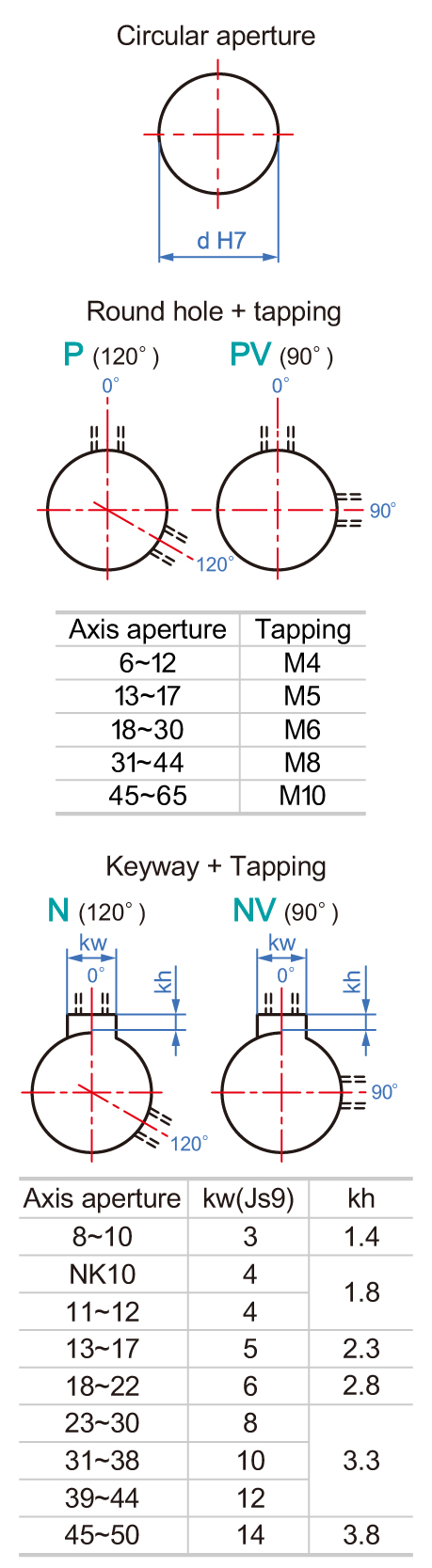

| Number of teeth | Modulu | A | Shape | Hole shape | d | D | Number of teeth | Dp | Do | W-shaped Surplus material processing | |

| Dp | Do | ||||||||||

| 15 | M3 | 28 | B | | 12~ | 36 | 15 | 45 | 51 | - | - |

| 16 | 38 | 16 | 48 | 54 | |||||||

| 17 | 40 | 17 | 51 | 57 | |||||||

| 18 | 42 | 18 | 54 | 60 | |||||||

| 19 | 47 | 19 | 57 | 63 | |||||||

| 20 | 50 | 20 | 60 | 66 | |||||||

| 21 | 55 | 21 | 63 | 69 | |||||||

| 22 | 55 | 22 | 66 | 72 | |||||||

| 23 | 60 | 23 | 69 | 75 | |||||||

| 24 | 60 | 24 | 72 | 78 | |||||||

| 25 | 65 | 25 | 75 | 81 | |||||||

| 26 | 65 | 26 | 78 | 84 | |||||||

| 27 | 68 | 27 | 81 | 87 | |||||||

| 28 | 70 | 28 | 84 | 90 | |||||||

| 29 | 75 | 29 | 87 | 93 | |||||||

| 30 | 75 | 30 | 90 | 96 | |||||||

| 31 | 85 | 31 | 93 | 99 | |||||||

| 32 | 85 | 32 | 96 | 102 | |||||||

| 33 | 90 | 33 | 99 | 105 | |||||||

| 34 | 15~ | 90 | 34 | 102 | 108 | ||||||

| 35 | 95 | 35 | 105 | 111 | |||||||

| 36 | 95 | 36 | 108 | 114 | |||||||

| 37 | 100 | 37 | 111 | 117 | |||||||

| 38 | 100 | 38 | 114 | 120 | |||||||

| 39 | 100 | 39 | 117 | 123 | |||||||

| 40 | 110 | 40 | 120 | 126 | |||||||

| 41 | 110 | 41 | 123 | 129 | |||||||

| 42 | 110 | 42 | 126 | 132 | |||||||

| 43 | 120 | 43 | 129 | 135 | |||||||

| 44 | 120 | 44 | 132 | 138 | |||||||

| 45 | 120 | 45 | 135 | 141 | |||||||

| 46 | 120 | 46 | 138 | 144 | |||||||

| 47 | 120 | 47 | 141 | 147 | |||||||

| 48 | 120 | 48 | 144 | 150 | |||||||

| 49 | 120 | 49 | 147 | 153 | |||||||

| 50 | 120 | 50 | 150 | 156 | 120 | S=Ax0.6 |