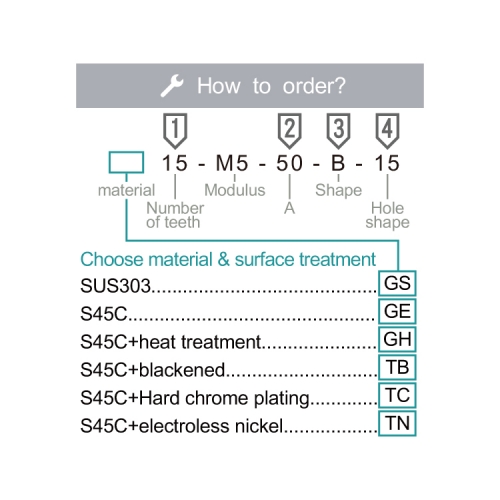

M5 module

Metal gear Pressure angle 20∘

Belt teeth

Type

Please select a size

Quantity

In stock

Remark

|

|

|

|

|

|

|

|

|

|

|

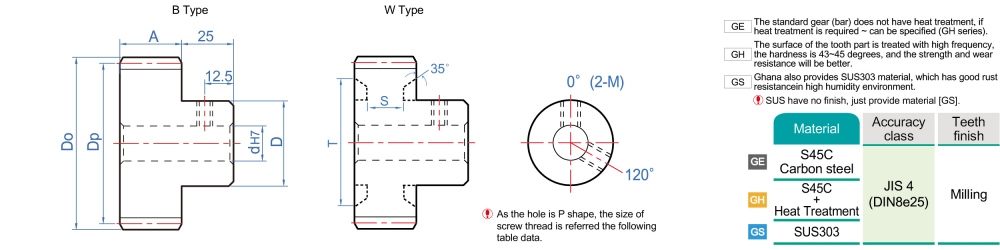

| unit:mm |

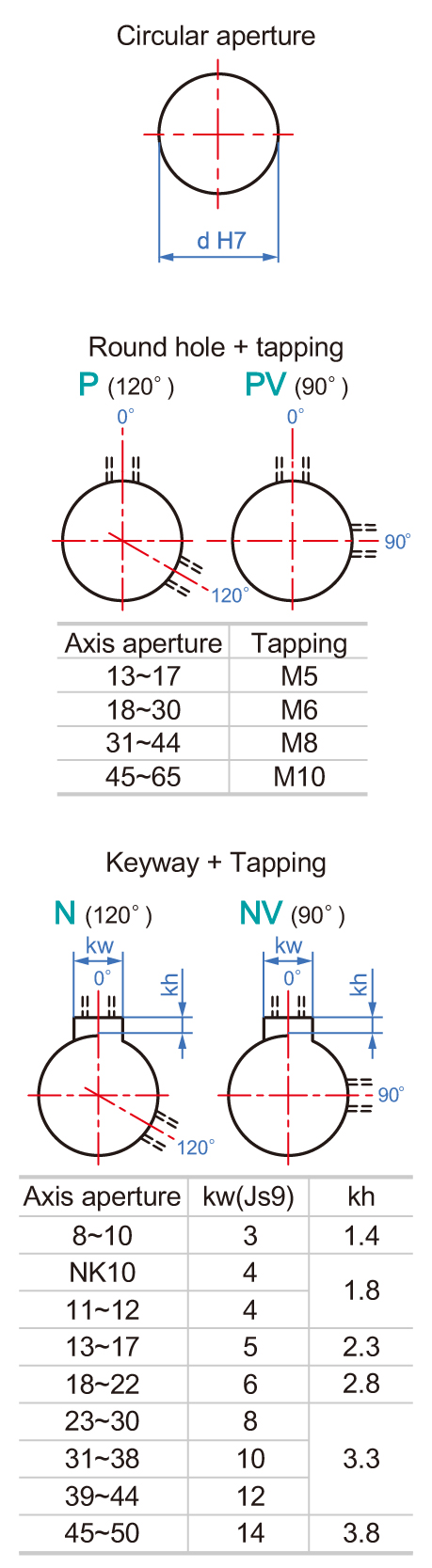

| Number | Modulus | A | Shape | Hole shape | d | D | Number | Dp | Do | W-shaped surplus material processing | |

| Dp | Do | ||||||||||

| 12 | M5 | 44 | B | | 15~ | 46 | 12 | 60 | 70 | - | - |

| 13 | 50 | 13 | 65 | 75 | |||||||

| 14 | 52 | 14 | 70 | 80 | |||||||

| 15 | 60 | 15 | 75 | 85 | |||||||

| 16 | 65 | 16 | 80 | 90 | |||||||

| 17 | 68 | 17 | 85 | 95 | |||||||

| 18 | 70 | 18 | 90 | 100 | |||||||

| 19 | 20~ | 76 | 19 | 95 | 105 | ||||||

| 20 | 82 | 20 | 100 | 110 | |||||||

| 21 | 90 | 21 | 105 | 115 | |||||||

| 22 | 95 | 22 | 110 | 120 | |||||||

| 23 | 100 | 23 | 115 | 125 | |||||||

| 24 | 24 | 120 | 130 | ||||||||

| 25 | 105 | 25 | 125 | 135 | |||||||

| 26 | 110 | 26 | 130 | 140 | |||||||

| 27 | 27 | 135 | 145 | ||||||||

| 28 | 28 | 140 | 150 | ||||||||

| 29 | 115 | 29 | 145 | 155 | |||||||

| 30 | 25~ | 120 | 30 | 150 | 160 | ||||||

| 32 | 32 | 160 | 170 | ||||||||

| 34 | 34 | 170 | 180 | ||||||||

| 35 | 35 | 175 | 185 | ||||||||

| 36 | 36 | 180 | 190 | ||||||||

| 38 | 38 | 190 | 200 | ||||||||

| 40 | 40 | 200 | 210 | 160 | S=Ax0.6 | ||||||

| 42 | 42 | 210 | 220 | 168 | |||||||

| 44 | 44 | 220 | 230 | 176 | |||||||

| 45 | 45 | 225 | 235 | 180 | |||||||

| 46 | 46 | 230 | 240 | 184 | |||||||

| 48 | 48 | 240 | 250 | 192 | |||||||

| 50 | 50 | 250 | 260 | 200 | |||||||

| 52 | 130 | 52 | 260 | 270 | 208 | ||||||

| 54 | 54 | 270 | 280 | 216 | |||||||

| 55 | 55 | 275 | 285 | 220 | |||||||

| 56 | 56 | 280 | 290 | 224 | |||||||

| 58 | 58 | 290 | 300 | 232 | |||||||

| 60 | 60 | 300 | 310 | 240 |