|

|

|

|

|

|

|

|

|

|

|

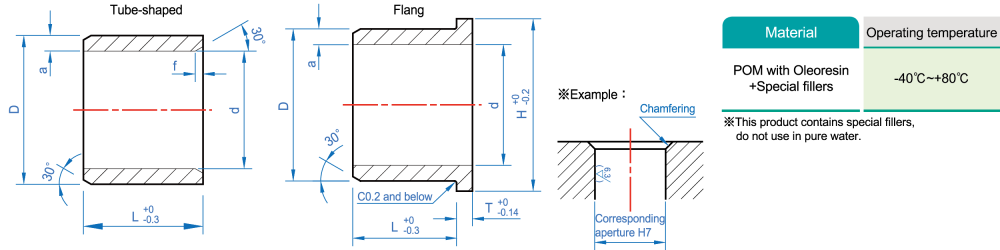

| unit:mm | |||||||||

| d | L | D | a | H | T | Recommended correspondence size | ||||||||||||||

| Tube-shaped | Flange | Mounting holes H7 | Shaft diameter g6 | |||||||||||||||||

| 3 | 3 | 5 |

|

|

| 3 |

|

|

|

| 5 | +0.210 | 1 | -0.015 | 8 | 1 | 5 | +0.012 | 3 | +0 |

| 4 | 4 | 6 |

|

|

| 4 | 6 |

|

|

| 6 | 1 | -0.023 | 9 | 6 | 4 | +0 | |||

| 5 | 5 | 8 |

|

|

| 4 | 5 | 7 |

|

| 7 | +0.270 | 1 | -0.025 | 10 | 7 | +0.015 | 5 | ||

| 6 | 5 | 6 | 8 | 10 |

| 5 | 6 | 8 |

|

| 8 | 12 | 8 | 6 | ||||||

| 8 | 6 | 8 | 10 | 12 | 15 | 6 | 8 | 10 |

|

| 10 | 15 | 10 | 8 | +0 | |||||

| 10 | 8 | 10 | 12 | 15 |

| 6 | 8 | 10 | 12 | 15 | 12 | +0.340 | 18 | 12 | +0.018 | 10 | ||||

| 12 | 10 | 12 | 15 | 20 |

| 6 | 8 | 10 | 12 | 15 | 14 | 20 | 14 | 12 | +0 | |||||

| 14 | 10 | 15 | 20 |

|

| 10 | 12 | 15 | 20 |

| 16 | 22 | 16 | 14 | ||||||

| 15 | 10 | 15 | 20 |

|

| 10 | 12 | 15 | 20 |

| 17 | 23 | 17 | 15 | ||||||

| 16 | 15 | 20 | 25 |

|

| 10 | 15 | 20 |

|

| 18 | 24 | 18 | 16 | ||||||

| 18 | 15 | 20 | 25 |

|

| 10 | 12 | 15 | 20 |

| 20 | +0.450 | 26 | 20 | +0.021 | 18 | ||||

| 20 | 10 | 15 | 20 | 25 | 30 | 10 | 15 | 20 | 25 |

| 23 | 1.5 | -0.027 | 31 | 1.5 | 23 | 20 | +0 | ||

| 22 | 20 | 30 |

|

|

| 10 | 15 | 20 | 25 |

| 25 | 33 | 25 | 22 | ||||||

| 25 | 20 | 25 | 30 |

|

| 10 | 15 | 20 | 25 | 30 | 28 | 36 | 28 | +0.025 | 25 | |||||

| 30 | 20 | 30 | 40 |

|

| 20 | 30 | 40 |

|

| 34 | +0.550 | 2 | -0.030 | 42 | 2 | 34 | 30 | ||

| ※All are permanent stores, L size allowed processing length to change shorter. Contact Chena to check. |

|

|

|

| Characteristics distinguish | Unit |

| Proportion | 1.47 |

| Tensile strength(MPa) | 60.8 |

| Extension(%) | 60 |

| Hardness(HRM) | 80 |

| Coefficient of expansion(X 10 /℃) | 9~13 |

| Friction coefficient( µ ) | 0.01~0.15 |

| The max. allowable(Mpa) | 20 |

| The max. allowable speed(m/min) | 60 |