| |||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 3 | 4 | 1.52 | 6 | 0.51 | 0.13 | 0.61 | 6.59 | 12 | 0.61 | 0.15 | 0.74 | 15.38 | CHENA CHENA CHENA CHENA | ||||

| 4 | 2.03 | 0.81 | 4.92 | 0.97 | 11.32 | |||||||||||||

| 5 | 2.54 | 1.02 | 3.95 | 1.22 | 9.09 | |||||||||||||

| 6 | 3.05 | 1.22 | 3.28 | 1.47 | 7.59 | |||||||||||||

| 7 | 3.56 | 1.42 | 2.8 | 1.7 | 6.45 | |||||||||||||

| 8 | 4.06 | 1.63 | 2.47 | 1.96 | 5.71 | |||||||||||||

| 9 | 4.57 | 1.83 | 2.19 | 2.18 | 5.02 | |||||||||||||

| 11 | 5.59 | 2.24 | 1.79 | 2.69 | 4.14 | |||||||||||||

| 13 | 6.6 | 2.64 | 1.52 | 3.18 | 3.51 | |||||||||||||

| 8 | 3 | 5 | 2.82 | 15 | 0.8 | 0.2 | 1.7 | 13.39 | 30 | 0.81 | 0.25 | 1.78 | 28.85 | |||||

| 4 | 3.76 | 2.39 | 10.95 | 2.54 | 24.59 | |||||||||||||

| 5 | 4.7 | 2.74 | 7.65 | 3.05 | 18.18 | |||||||||||||

| 6 | 5.64 | 3.56 | 7.21 | 3.81 | 16.39 | |||||||||||||

| 7 | 6.58 | 4.01 | 5.84 | 4.32 | 13.27 | |||||||||||||

| 8 | 7.52 | 4.57 | 5.08 | 4.95 | 11.67 | |||||||||||||

| 9 | 8.46 | 5.26 | 4.69 | 5.59 | 10.45 | |||||||||||||

| 11 | 10.34 | 6.35 | 3.76 | 6.86 | 8.62 | |||||||||||||

| 13 | 12.22 | 7.37 | 3.09 | 7.87 | 6.9 | |||||||||||||

| 10 | 3 | 7 | 3.96 | 18 | 0.8 | 0.2 | 1.91 | 8.78 | 35 | 0.81 | 0.28 | 2.03 | 18.13 | |||||

| 4 | 5.28 | 2.54 | 6.57 | 2.79 | 14.06 | |||||||||||||

| 5 | 6.6 | 3.15 | 5.22 | 3.56 | 11.51 | |||||||||||||

| 6 | 7.92 | 3.78 | 4.35 | 4.32 | 9.72 | |||||||||||||

| 7 | 9.25 | 4.42 | 3.73 | 5.08 | 8.39 | |||||||||||||

| 8 | 10.57 | 5.05 | 3.26 | 5.84 | 7.4 | |||||||||||||

| 9 | 11.89 | 5.69 | 2.9 | 6.6 | 6.62 | |||||||||||||

| 10 | 13.21 | 6.32 | 2.61 | 7.37 | 5.99 | |||||||||||||

| 11 | 14.53 | 6.96 | 2.38 | 8.13 | 5.47 | |||||||||||||

| 12 | 3 | 9 | 4.34 | 20 | 1 | 0.2 | 1.47 | 6.97 | 40 | 1.17 | 0.28 | 2.36 | 20.2 | 60 | 1.14 | 0.3 | 1.98 | 25.42 |

| 4 | 5.79 | 1.98 | 5.25 | 3.18 | 15.33 | 2.64 | 19.05 | |||||||||||

| 5 | 7.24 | 2.46 | 4.18 | 3.96 | 12.2 | 3.3 | 15.23 | |||||||||||

| 6 | 8.69 | 2.95 | 3.48 | 4.75 | 10.15 | 3.99 | 12.77 | |||||||||||

| 7 | 10.13 | 3.45 | 2.99 | 5.54 | 8.71 | 4.65 | 10.95 | |||||||||||

| 8 | 11.58 | 3.94 | 2.62 | 6.32 | 7.6 | 5.31 | 9.57 | |||||||||||

| 9 | 13.03 | 4.45 | 2.33 | 7.11 | 6.76 | 5.97 | 8.5 | |||||||||||

| 10 | 14.48 | 4.93 | 2.09 | 7.92 | 6.1 | 6.63 | 7.64 | |||||||||||

| 11 | 15.93 | 5.44 | 1.91 | 8.71 | 5.54 | 7.29 | 6.94 | |||||||||||

| 14 | 3 | 10 | 4.95 | 22 | 1.5 | 0.23 | 2.18 | 7.94 | 50 | 1.52 | 0.3 | 2.18 | 18.05 | 80 | 1.52 | 0.38 | 3.15 | 44.44 |

| 4 | 6.6 | 2.95 | 6.03 | 2.95 | 13.7 | 4.19 | 33.2 | |||||||||||

| 5 | 8.26 | 3.71 | 4.84 | 3.71 | 10.99 | 5.26 | 26.67 | |||||||||||

| 6 | 9.91 | 4.52 | 4.08 | 4.52 | 9.28 | 6.3 | 22.16 | |||||||||||

| 7 | 11.56 | 5.33 | 3.53 | 5.33 | 8.03 | 7.34 | 18.96 | |||||||||||

| 8 | 13.21 | 6.17 | 3.13 | 6.17 | 7.1 | 8.41 | 16.67 | |||||||||||

| 9 | 14.86 | 7.01 | 2.8 | 7.01 | 6.37 | 9.45 | 14.79 | |||||||||||

| 10 | 16.51 | 7.85 | 2.54 | 7.85 | 5.77 | 10.49 | 13.29 | |||||||||||

| 11 | 18.16 | 8.71 | 2.33 | 8.71 | 5.29 | 11.56 | 12.12 | |||||||||||

| 15 | 3 | 11 | 5.18 | 25 | 1.5 | 0.25 | 2.57 | 9.58 | 50 | 1.47 | 0.23 | 3.43 | 28.57 | 80 | 1.47 | 0.25 | 3.2 | 40.4 |

| 4 | 6.91 | 3.43 | 7.18 | 4.57 | 21.37 | 4.19 | 29.41 | |||||||||||

| 5 | 8.64 | 4.27 | 5.72 | 5.72 | 17.12 | 5.26 | 23.46 | |||||||||||

| 6 | 10.36 | 5.13 | 4.78 | 6.86 | 14.29 | 6.27 | 19.56 | |||||||||||

| 7 | 12.09 | 5.99 | 4.1 | 8 | 12.22 | 7.32 | 16.77 | |||||||||||

| 8 | 13.82 | 6.83 | 3.58 | 9.14 | 10.68 | 8.36 | 14.65 | |||||||||||

| 9 | 15.54 | 7.7 | 3.19 | 10.29 | 9.52 | 9.4 | 13.03 | |||||||||||

| 10 | 17.27 | 8.53 | 2.86 | 11.43 | 8.56 | 10.46 | 11.75 | |||||||||||

| 11 | 19 | 9.4 | 2.6 | 12.57 | 7.78 | 11.51 | 10.68 | |||||||||||

| 16 | 3 | 11 | 5.41 | 25 | 1.5 | 0.25 | 2.11 | 7.58 | 55 | 1.47 | 0.25 | 3.63 | 30.9 | 90 | 1.52 | 0.3 | 3.3 | 42.65 |

| 4 | 7.21 | 2.79 | 5.66 | 4.83 | 23.11 | 4.57 | 34.09 | |||||||||||

| 5 | 9.02 | 3.51 | 4.54 | 6.05 | 18.52 | 5.59 | 26.24 | |||||||||||

| 6 | 10.82 | 4.19 | 3.77 | 7.24 | 15.36 | 6.86 | 22.73 | |||||||||||

| 7 | 12.62 | 4.9 | 3.24 | 8.46 | 13.22 | 7.87 | 18.95 | |||||||||||

| 9 | 16.23 | 6.3 | 2.52 | 10.87 | 10.26 | 10.16 | 14.83 | |||||||||||

| 11 | 19.84 | 7.7 | 2.06 | 13.28 | 8.38 | 12.45 | 12.18 | |||||||||||

| 13 | 23.44 | 9.09 | 1.74 | 15.7 | 7.11 | 14.73 | 10.33 | |||||||||||

| 18 | 3 | 13 | 5.72 | 30 | 1.8 | 0.2 | 3.63 | 14.35 | 55 | 1.83 | 0.25 | 3.68 | 26.96 | 90 | 1.83 | 0.3 | 3.84 | 47.87 |

| 4 | 7.62 | 4.75 | 10.45 | 4.98 | 20.83 | 5.13 | 36.14 | |||||||||||

| 5 | 9.53 | 5.94 | 8.36 | 6.22 | 16.62 | 6.4 | 28.75 | |||||||||||

| 6 | 11.43 | 7.14 | 6.99 | 7.47 | 13.89 | 7.7 | 24.13 | |||||||||||

| 7 | 13.34 | 8.31 | 5.96 | 8.47 | 11.96 | 8.97 | 20.59 | |||||||||||

| 9 | 17.15 | 10.69 | 4.64 | 11.23 | 9.29 | 11.53 | 16.01 | |||||||||||

| 12 | 22.86 | 14.25 | 3.48 | 14.96 | 6.96 | 15.37 | 12.02 | |||||||||||

| 20 | 3 | 15 | 6.32 | 35 | 1.8 | 0.2 | 2.72 | 9.27 | 70 | 1.98 | 0.25 | 3.05 | 21.41 | 100 | 2.01 | 0.33 | 4.24 | 48.08 |

| 4 | 8.43 | 3.61 | 7.26 | 4.06 | 16.02 | 5.66 | 36.1 | |||||||||||

| 5 | 10.54 | 4.52 | 5.81 | 5.08 | 12.82 | 7.06 | 28.74 | |||||||||||

| 6 | 12.65 | 5.41 | 4.83 | 6.27 | 10.97 | 8.48 | 23.98 | |||||||||||

| 7 | 14.76 | 6.32 | 4.15 | 7.32 | 9.41 | 9.91 | 20.62 | |||||||||||

| 9 | 18.97 | 8.13 | 3.23 | 9.17 | 7.14 | 12.73 | 16.03 | |||||||||||

| 12 | 25.3 | 10.82 | 2.42 | 12.22 | 5.35 | 16.97 | 12 | |||||||||||

| 25 | 3 | 19 | 6.63 | 50 | 2.2 | 0.25 | 2.06 | 10.94 | 80 | 2.39 | 0.3 | 2.95 | 21.74 | 110 | 2.39 | 0.38 | 4.04 | 42.47 |

| 4 | 8.84 | 2.74 | 8.2 | 3.9 | 16.33 | 5.38 | 31.79 | |||||||||||

| 5 | 11.05 | 3.43 | 6.56 | 4.9 | 13.01 | 6.73 | 25.46 | |||||||||||

| 6 | 13.26 | 4.11 | 5.46 | 5.89 | 10.85 | 8.08 | 21.24 | |||||||||||

| 7 | 15.47 | 4.8 | 4.69 | 6.88 | 9.31 | 9.4 | 18.12 | |||||||||||

| 9 | 19.89 | 6.2 | 3.65 | 8.843 | 7.24 | 12.12 | 14.16 | |||||||||||

| 12 | 26.52 | 8.26 | 2.74 | 11.79 | 5.43 | 16.15 | 10.61 | |||||||||||

| 28 | 3 | 22 | 7.24 | 50 | 2.4 | 0.3 | 3.76 | 14.37 | 80 | 2.39 | 0.38 | 4.39 | 28.07 | 130 | 2.39 | 0.46 | 4.57 | 48.69 |

| 4 | 9.65 | 5 | 10.75 | 5.84 | 21 | 6.07 | 36.31 | |||||||||||

| 5 | 12.07 | 6.27 | 8.62 | 7.32 | 16.84 | 7.59 | 29.02 | |||||||||||

| 6 | 14.48 | 7.52 | 7.18 | 8.79 | 14.06 | 9.12 | 24.25 | |||||||||||

| 7 | 16.89 | 8.79 | 6.17 | 10.24 | 12.03 | 10.64 | 20.8 | |||||||||||

| 8 | 19.3 | 10.03 | 5.39 | 11.71 | 10.54 | 12.17 | 18.23 | |||||||||||

| 9 | 21.72 | 11.28 | 4.79 | 13.18 | 9.37 | 13.69 | 16.19 | |||||||||||

| 11 | 26.54 | 13.79 | 3.92 | 16.1 | 7.66 | 16.71 | 13.22 | |||||||||||

| 13 | 31.37 | 16.31 | 3.32 | 19.02 | 6.48 | 19.76 | 11.2 | |||||||||||

| 30 | 3 | 24 | 7.62 | 50 | 2.4 | 0.3 | 3.18 | 11.26 | 90 | 2.39 | 0.38 | 7.62 | 21.9 | 130 | 2.39 | 0.46 | 7.62 | 37.9 |

| 4 | 10.16 | 4.22 | 8.42 | 10.16 | 16.48 | 10.16 | 28.45 | |||||||||||

| 5 | 12.7 | 5.28 | 6.74 | 12.7 | 13.18 | 12.7 | 22.77 | |||||||||||

| 6 | 15.24 | 6.32 | 5.61 | 15.24 | 10.98 | 15.24 | 18.95 | |||||||||||

| 7 | 17.78 | 7.39 | 4.81 | 17.78 | 9.39 | 17.78 | 16.25 | |||||||||||

| 8 | 20.32 | 20.32 | 4.21 | 20.32 | 8.22 | 20.32 | 14.22 | |||||||||||

| 9 | 22.86 | 22.86 | 3.74 | 22.86 | 7.31 | 22.86 | 12.63 | |||||||||||

| 11 | 27.94 | 27.94 | 3.06 | 27.94 | 5.98 | 27.94 | 10.34 | |||||||||||

| 13 | 33.02 | 33.02 | 2.59 | 33.02 | 5.06 | 33.02 | 8.75 | |||||||||||

| 35 | 3 | 27 | 8.38 | 70 | 3.2 | 0.36 | 3.94 | 15.77 | 110 | 3.38 | 0.41 | 4.14 | 25.94 | 160 | 3.38 | 0.46 | 4.04 | 36.87 |

| 4 | 11.18 | 5.23 | 11.76 | 5.51 | 19.4 | 5.38 | 27.59 | |||||||||||

| 5 | 13.97 | 6.55 | 9.43 | 6.88 | 15.51 | 6.73 | 22.1 | |||||||||||

| 6 | 16.76 | 7.87 | 7.87 | 8.26 | 12.94 | 8.08 | 18.43 | |||||||||||

| 7 | 19.56 | 9.17 | 6.74 | 9.63 | 11.08 | 9.42 | 15.78 | |||||||||||

| 8 | 22.35 | 10.49 | 5.9 | 11.02 | 9.71 | 10.77 | 13.82 | |||||||||||

| 9 | 25.15 | 11.81 | 5.25 | 12.4 | 8.63 | 12.12 | 12.28 | |||||||||||

| 11 | 30.73 | 14.43 | 4.29 | 15.14 | 7.06 | 14.81 | 10.05 | |||||||||||

| 13 | 36.32 | 17.04 | 3.63 | 17.91 | 5.98 | 17.5 | 8.5 | |||||||||||

| 40 | 3 | 30 | 9.14 | 100 | 3.38 | 0.41 | 2.90 | 16.03 | 150 | 3.63 | 0.53 | 5.44 | 40.54 | 300 | 3.38 | 0.46 | 5.66 | 86.21 |

| 4 | 12.19 | 3.86 | 12.00 | 7.24 | 30.30 | 7.54 | 64.52 | |||||||||||

| 5 | 15.24 | 4.80 | 9.58 | 9.04 | 24.19 | 9.42 | 51.55 | |||||||||||

| 6 | 18.29 | 5.77 | 7.99 | 10.85 | 20.16 | 11.33 | 43.10 | |||||||||||

| 7 | 21.34 | 6.73 | 6.84 | 12.65 | 17.26 | 13.21 | 36.90 | |||||||||||

| 8 | 24.38 | 7.70 | 6.00 | 14.48 | 15.15 | 15.09 | 32.29 | |||||||||||

| 9 | 27.43 | 8.66 | 5.33 | 16.28 | 13.45 | 16.97 | 28.68 | |||||||||||

| 11 | 33.53 | 10.59 | 4.36 | 19.89 | 11.00 | 20.75 | 23.47 | |||||||||||

| 13 | 39.62 | 12.52 | 3.69 | 23.50 | 9.31 | 24.54 | 19.89 | |||||||||||

| 45 | 3 | 35 | 9.91 | 110 | 3.63 | 0.46 | 3.38 | 16.85 | 225 | 3.63 | 0.46 | 5.33 | 49.13 | 400 | 3.76 | 0.61 | 6.43 | 114.94 |

| 4 | 13.21 | 4.52 | 12.66 | 6.99 | 36.17 | 8.38 | 82.82 | |||||||||||

| 5 | 16.51 | 5.64 | 10.12 | 9.14 | 30.53 | 11.2 | 75.33 | |||||||||||

| 6 | 19.81 | 6.76 | 8.43 | 10.8 | 24.97 | 12.95 | 58.31 | |||||||||||

| 7 | 23.11 | 7.9 | 7.23 | 12.7 | 21.61 | 15.37 | 51.68 | |||||||||||

| 8 | 26.42 | 9.02 | 6.32 | 14.48 | 18.84 | 17.27 | 43.72 | |||||||||||

| 9 | 29.72 | 10.16 | 5.62 | 16.26 | 16.72 | 19.68 | 39.88 | |||||||||||

| 11 | 36.32 | 12.4 | 4.6 | 19.81 | 13.63 | 24.26 | 33.17 | |||||||||||

| 13 | 42.93 | 14.66 | 3.89 | 23.37 | 11.5 | 28.45 | 27.62 | |||||||||||

| 50 | 3 | 40 | 10.29 | 110 | 3.63 | 0.53 | 4.83 | 20.15 | 225 | 3.63 | 0.46 | 4.62 | 39.68 | 400 | 3.76 | 0.61 | 5.92 | 91.53 |

| 4 | 13.72 | 6.10 | 14.44 | 6.35 | 30.53 | 7.80 | 67.57 | |||||||||||

| 5 | 17.15 | 7.87 | 11.85 | 7.49 | 23.29 | 10.16 | 57.22 | |||||||||||

| 6 | 20.57 | 9.40 | 9.85 | 8.89 | 19.26 | 11.79 | 45.56 | |||||||||||

| 7 | 24.00 | 11.30 | 8.66 | 10.54 | 16.72 | 14.15 | 40.61 | |||||||||||

| 8 | 27.43 | 12.70 | 7.47 | 11.89 | 14.48 | 15.62 | 33.87 | |||||||||||

| 9 | 30.86 | 14.99 | 6.93 | 13.59 | 13.03 | 17.91 | 30.89 | |||||||||||

| 11 | 37.72 | 18.16 | 5.62 | 16.71 | 10.71 | 21.54 | 24.72 | |||||||||||

| 13 | 44.58 | 21.34 | 4.73 | 19.61 | 9.01 | 25.65 | 21.13 | |||||||||||

| 15 | 51.44 | 24.64 | 4.10 | 22.48 | 7.77 | 29.21 | 17.99 | |||||||||||

| 55 | 3 | 45 | 11.05 | 125 | 3.76 | 0.61 | 5.59 | 22.89 | 250 | 3.63 | 0.46 | 3.10 | 31.45 | 400 | 3.76 | 0.61 | 5.31 | 69.69 |

| 4 | 14.73 | 7.72 | 17.83 | 4.11 | 23.54 | 7.24 | 53.40 | |||||||||||

| 5 | 18.41 | 9.68 | 14.30 | 5.16 | 18.85 | 9.09 | 42.87 | |||||||||||

| 6 | 22.10 | 11.48 | 11.77 | 6.20 | 15.72 | 10.64 | 34.90 | |||||||||||

| 7 | 25.78 | 13.92 | 10.54 | 7.21 | 13.46 | 12.24 | 29.54 | |||||||||||

| 8 | 29.46 | 15.52 | 8.97 | 8.26 | 11.79 | 14.10 | 26.04 | |||||||||||

| 9 | 33.15 | 18.41 | 8.49 | 9.27 | 10.47 | 15.82 | 23.08 | |||||||||||

| 11 | 40.51 | 21.67 | 6.63 | 11.33 | 8.57 | 19.30 | 18.86 | |||||||||||

| 13 | 47.88 | 25.65 | 5.62 | 13.41 | 7.25 | 23.11 | 16.15 | |||||||||||

| 15 | 55.25 | 29.77 | 4.91 | 15.47 | 6.28 | 26.54 | 13.93 | |||||||||||

| 60 | 3 | 50 | 11.43 | 135 | 3.63 | 0.46 | 5.59 | 23.12 | 275 | 3.76 | 0.61 | 6.65 | 57.53 | 450 | 4.01 | 0.76 | 7.75 | 122.28 |

| 4 | 15.24 | 7.47 | 17.37 | 8.86 | 43.10 | 10.31 | 91.28 | |||||||||||

| 5 | 19.05 | 9.32 | 13.87 | 11.07 | 34.46 | 12.90 | 73.17 | |||||||||||

| 6 | 22.86 | 11.20 | 11.58 | 13.28 | 28.71 | 15.47 | 60.89 | |||||||||||

| 7 | 26.67 | 13.06 | 9.92 | 15.49 | 24.60 | 18.06 | 52.26 | |||||||||||

| 8 | 30.48 | 14.94 | 8.69 | 17.70 | 21.52 | 20.62 | 45.64 | |||||||||||

| 9 | 34.29 | 16.79 | 7.71 | 19.94 | 19.16 | 23.22 | 40.65 | |||||||||||

| 11 | 41.91 | 20.52 | 6.31 | 24.36 | 15.67 | 28.37 | 33.23 | |||||||||||

| 13 | 49.53 | 24.26 | 5.34 | 28.78 | 13.25 | 33.53 | 28.13 | |||||||||||

| 15 | 57.15 | 27.99 | 4.63 | 33.22 | 11.49 | 38.68 | 24.36 | |||||||||||

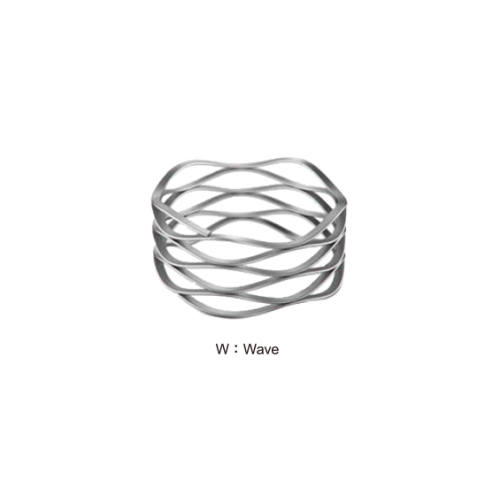

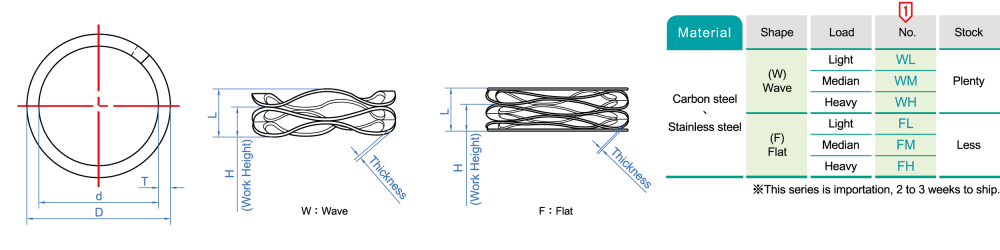

The corrugated spring material is a pre-tempered wire with a rounded-ended round head. Its smooth appearance and circularly wound sinusoidal wave shape make the product performance better than traditional stamping parts; if the load and spring coefficient are more accurate and more It is expected to save 50% space compared to stampings. Wave springs provide users with greater reliability and better performance. Since the spring is made of cold-rolled pre-tempered wire, there is no deformation during the hardening heat treatment. Overall, the mechanical properties and dimensional stability of the wave springs are ideal for applications requiring precision quality. The top wave spring is continuously wound and stacked by a coil of wire, and the elastic coefficient and the spring ring.

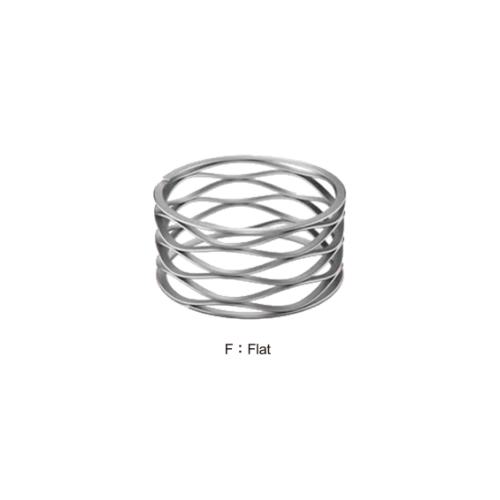

Flat end to top wave spring

The top wave spring is also offered with a flat end option. The flat end-to-top wave spring has a 360-degree annular contact surface. When the spring is in close contact with the fitting under the force, the force distribution of the flat end to the top wave spring is more uniform, and can also be stacked to meet the matching with the spare parts.